We safely practice sound engineering principles, basing decisions on factual, repeatable and quantifiable data. We recognize that instruments and technology rely on people with the skills, knowledge and experience to interpret such data in order to predict and ultimately prevent machine failure.

We stand proud in our strong offering that cost associated with most failures are avoidable and machinery life maximized.

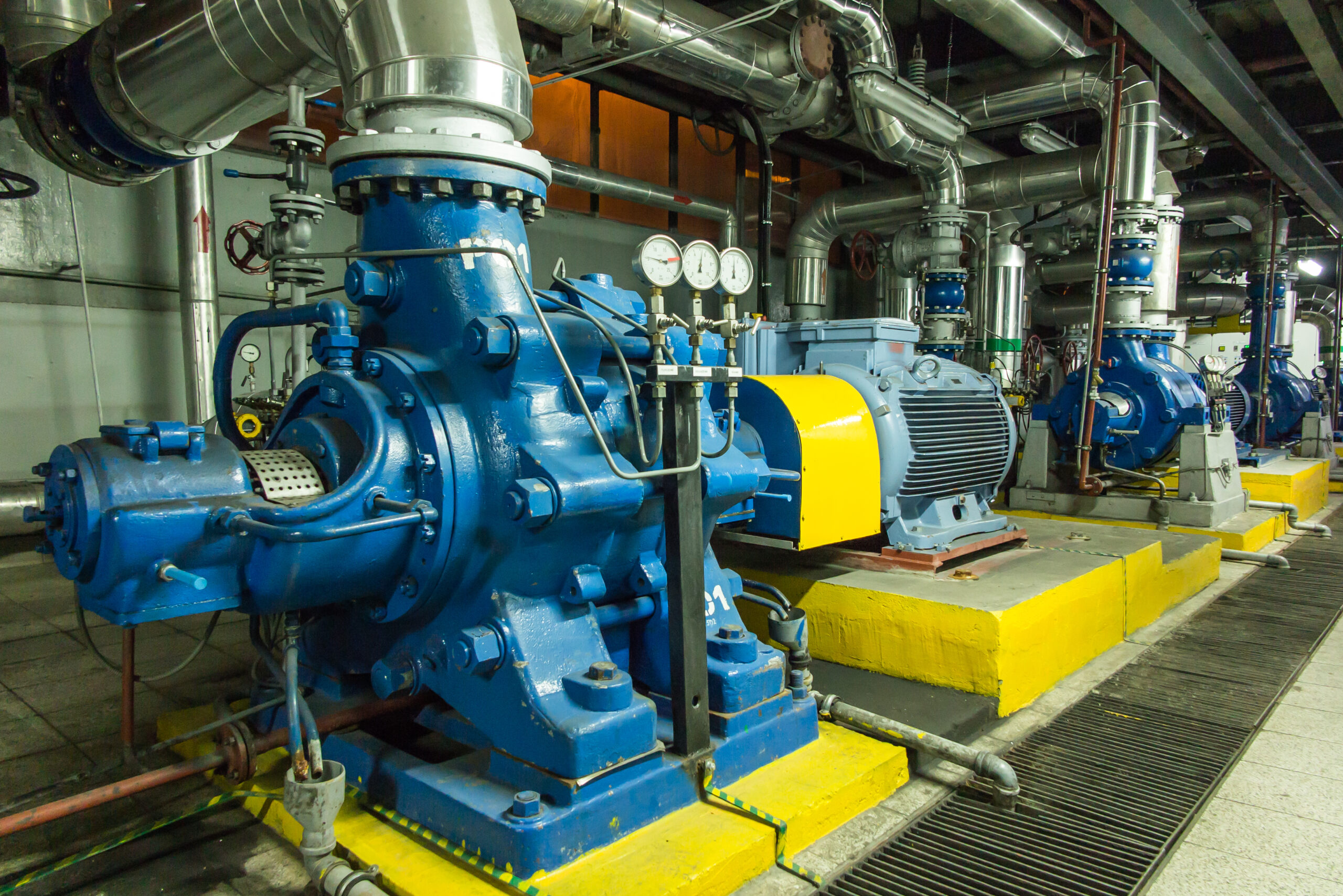

We offer Machinery Life Maximization and Condition Based Maintenance Consultancy services applicable to a wide range of industries from Maritime, Mining to Energy & Steel sectors. Specializing in Advanced Maintenance Engineering & Reliability including Rotating Machinery Condition Monitoring, Machinery Vibration Analysis, Lubrication Oil Analysis & Tribology, Ultrasound, Thermography, Laser Alignment, In-Situ Balancing, Ultrasonic Thickness Analysis, Pump Performance Tests, Quality Control / Quality Assurance & Maintenance Validation, Transient Data Capture during commissioning, Remote Accelerometer Installation, Modal Analysis and Training / Knowledge Transfer Partnership.